Mechanical Testing

Broad Range of Mechanical Testing Services

Measuring the mechanical properties of materials and components can help you determine their durability and give you insight into performance and suitability. Ensuring that materials and components fit their intended applications, mechanical testing services include tension and compression, both under static and dynamic loading conditions, bending, torsion, multi-axial tension-torsion, impact and crushing, fracture toughness, fatigue, and many more.

TECHSPERT mechanical testing lab offers a wide range of testing to evaluate composites, polymers, metals, additive manufactured materials and finished products. Whether you need to test to a standard method or develop a custom testing program, we are equipped to provide the answers and data you need.

Whatever the testing objective, TECHSPERT is well-equipped to provide the optimal solution to your challenging testing requirements.

Testing expertise:

Testing expertise:

- Standard and custom test programs

- High quality test data and analysis

- Comprehensive test reports, raw and processed data files

- Custom datasets for simulation and validation

- Decades of combined mechanical testing experience

TECHSPERT offers a wide variety of mechanical testing services in many loading conditions, loading rates, and environmental conditions.

Load Range

Test frequency

Environmental range

10% to 95% humidity

Load Range

Test frequency

Environmental range

10% to 95% humidity

Our extensive range of mechanical testing services, include:

Our extensive range of mechanical testing services, include:

- Standard test methods (ASTM, ISO, …) on calibrated load frames

- Creep and relaxation tests

- Static tests

- Instrumented dynamic drop weight impact

- High-strain rate tests

- Multi-axial tension/torsion fatigue

- Tension and compression fatigue

- Fracture toughness

- Fatigue crack growth

- Digital image correlation

- High speed imaging

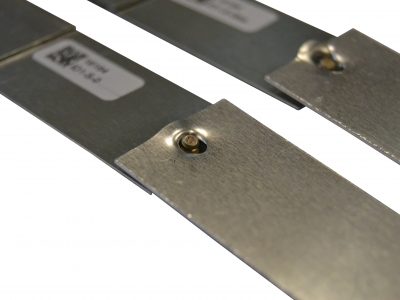

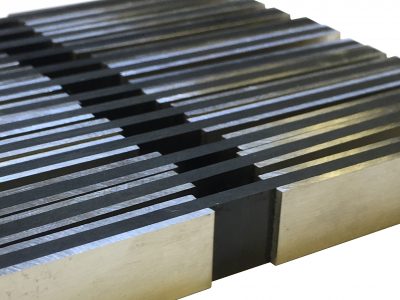

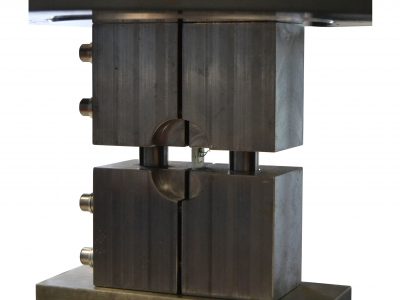

Custom design of test fixtures and mounting solutions

Custom design of test fixtures and mounting solutions

TECHSPERT has a versatile inventory of test fixtures to meet a wide range of testing requirements. For non-standard custom testing, engineers will work closely with you to develop new and/or specialized mounting fixtures fitting your particular test application.

Application Examples: Rivet Joint Lap Shear Tension Strength

Tensile lap shear test of a rivet joint assembly. In-situ camera monitoring is used to record the overall mechanical behaviour during the loading of the sample together with synched data capture animations.

Application Examples: Dynamic Composite Tube Crushing Test

Composite winded tubes are crushed to analyze the energy absorption properties of materials. In-situ high speed camera monitorring records the full failure crushing event of the tubes and can be linked to synchronized load, displacement, speed and acceleration data.